ENVIRONMENTAL ASPECTS

Nobody can abdicate one´s environmental responsibility in our days. Neither the consumers, nor politicians, nor the industry. Especially when it comes to the production and usage of mobile buildings the saving of energy and resources is extremely important.

We are aware of the importance to use our resources and energy sparingly. Therefore we want to make a helpful contribution to an ecological balance by means of pneumocell in comparison to other systems of mobile architecture

To put it bluntly: A building-material where the production, usage and disposal is a benefit for nature does not exist. But we have the possibility and the moral responsibility to spare resources and energy, produce as little waste as possible and make our waste non-toxic. So that nature only will be polluted in an impact that lies within its capabilities of regeneration.

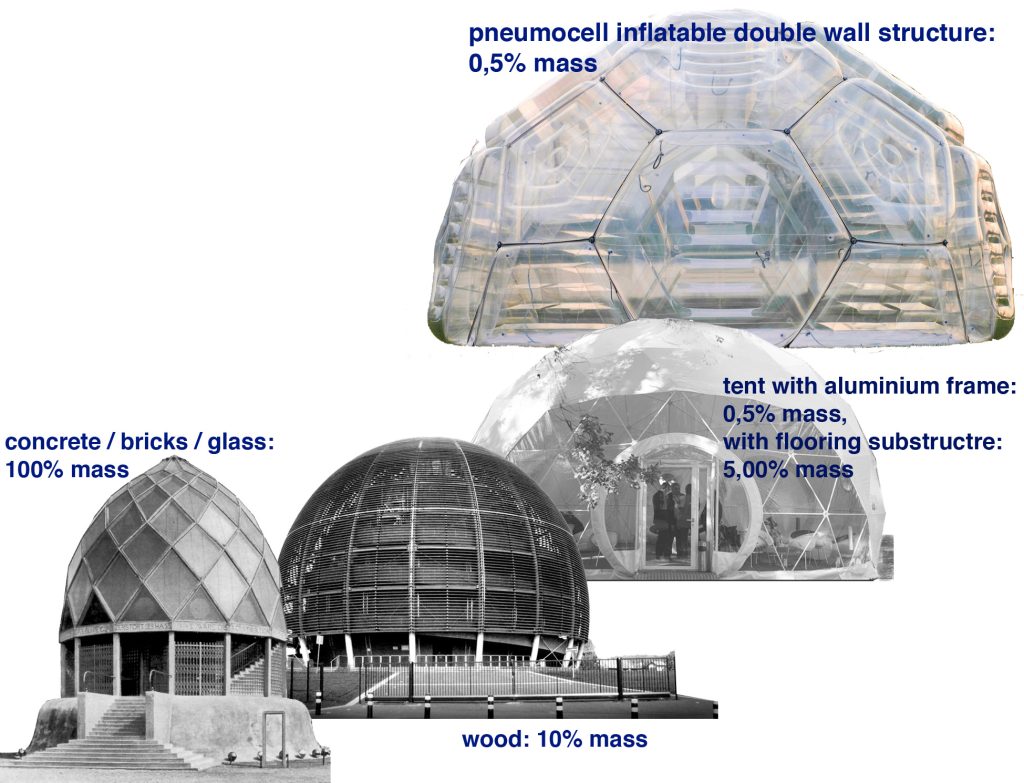

Pneumocell-advantage no.1: minimal mass

A double-wall inflated pneumocell-construction has 400 times less mass than a building made of brick and concrete of same size, 40 times less weight than a wooden building, and still half the weight only of an ordinary tent with single-layered membrane.

The low mass of pneumocell provides advantages not only in production but particularaly for multiple transportation for common mobile exhibition stalls.

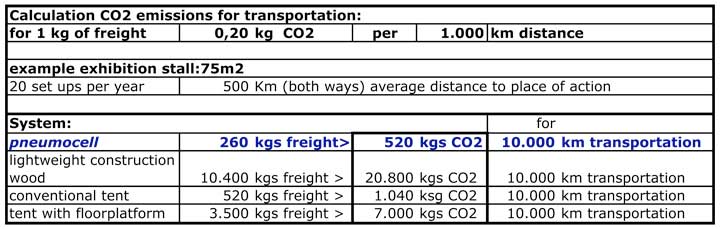

We assume that a typical Pneumocell-dome with 10m diameter and 6m height is built up 20 times per year for events and exhibitions. For the transportation of that dome 520kgs of CO2 are emitted annually.

For the same transportation of a wooden stall with the same size but 40 times heavier, 20.800 kgs of CO2 would be emitted.

Even a conventional tent has twice the mass and therefore causes twice the amount of emissions.

But unlike pneumocell contructions conventional tents cannot be placed on uneven grounds since the rigid aluminium framework cannot adapt and take deformations. Therefore a heavy floorplatform is required which multiplies the tents weight. Furthermore big tents mostly can only be set up by means of scaffolding and cranes.

Therefore the seemingly low weight of tents only rarely provides the expected advantages in reality.

Pneumocell- advantage no.2: Material

The framework of tents is usually made out of aluminum which spends a lot of energy in the production. The tarpaulin which is used mostly for traditional tents contains PVC.

Pneumocell elements consist out of pure TPU (thermoplastic polyurethane) which is 100% recyclable. Unlike PVC this material burns residue free and without emitting any toxic exhaust fumes. TPU does not contain any plasticizers nor chlorine, which are permanently emitted by other kinds of soft plastic materials accompanied by the typical „plastic-odor“

Even wood as a natural regenerative building material very rarely is used in its pure form. When made as plywood or pressboards it contains glue from synthetic resin and formaldehyde. Even paint finish and impregnations turn this natural material into hazardous waste

Pneumocell- advantage no.3: Assembly kit

Some exhibition stalls are only used once, and then disposed right after. Reasons are that striping down is not possible without demolishing the components of construction, or that there is no further use for this special construction.

Whereas you can re-assemble the same pneumocell-element many times to build new kinds of construction and adapt them to new premises. Therefore one benefits from the multiple usage of pneumocells for different applications; and the environment benefits as well because less mass needs be produced, transported and disposed.